-40%

Well Water Filter (3) Big Blue 20"x4.5"-1" W/PR-Sediment/KDF85 GAC/Carbon Block

$ 142.03

- Description

- Size Guide

Description

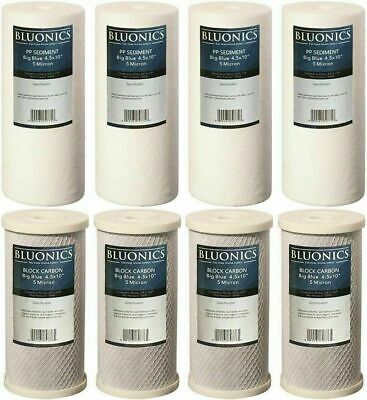

Whole House Water Filters - 3 Stage - Bracket Frame Stand Mounted - 3 Stage & WrenchFilters (20" X 4.5") Included:

Stage 1 - Sediment Water Filter 5 Mic

Stage 2 - Activated GAC Water/KDF 85 Mixed Media Filter Cartridge

Stage 3 - Activated Carbon Block CTO - 5 Mic

Filter Size - 20" x 4.5"

Suitable for whole house & light commercial application

Filters Specification:

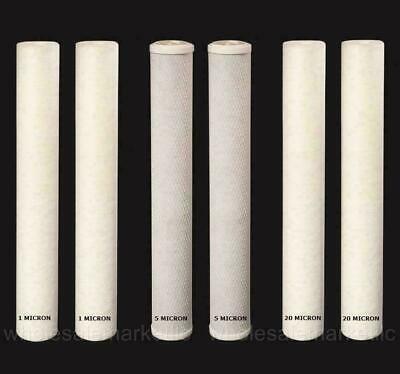

Stage 1

:

- 5 Micron PP Spun Polypropylene Sediment water Filter

- Maximum Flow Capacity: 25 GPM

- Maximum operating pressure: 125 PSI

- Dimensions: 20" x 4.5" , I.D. 1-1/8"

- Material Polypropylene

- Operation Temperature: 40°F to 125°F

- Filter Life: Recommended this filter to be changed every 6 months

Stage 2:

- KDF85/GAC Activated Carbon removes organic contaminants to substantially

improve water clarity,taste and odor. It does not add any harmful chemicals

to water, making it safe for drinking water applications.

The KDF85 Media removes or reduces iron and hydrogen sulfide from water

supplies, also controls scale,bacteria and algae. The KDF Iron/Hydrogen Sulfide

reduction filter contains a combination of KDF85 media and coconut shell activated

carbon (GAC). KDF85 effectively reduces dissolved iron and hydrogen sulfide odor.

Protecting your plumbing system including toilets,bath tubs,showers and appliances

such as clothes washers and dishwashers from unsightly staining and odor.

Stage 3:

- Carbon Block Filter strains out sediment, dirt, bacteria, microscopic worms,

algae, VOCs and cryptosporidium. With water pressure, this compacted

solid carbon block is designed to filter sub micron size particles.

Note: This system should be used where low to moderate ferrous (dissolved) iron or

hydrogen sulfide contamination is know. This filter is most effective where iron and

hydrogen sulfide levels are less than 5 ppm. Best removal rates are achieved where

pH is between 6.5 ~ 8.5 and where water contains some dissolved oxygen.

Note:

**Hydrogen sulfide concentrations exceeding 7 to 10 ppm can be removed by injecting an oxidizing chemical such as household bleach followed up by filtration. The oxidizing chemical should enter the water upstream from the storage or mixing tank to provide at least 30-45 minutes of contact time between the chemical and water. The length of length of the holding time is a function of the chemical dosage, tank configuration and water temperature. Sulfur particles can then be removed using a sediment filter and the excess chlorine can be removed by activated carbon filtration.

If test results indicate that bacterial contamination is occurring, shock chlorination or disinfection is the most widely suggested method for initial treatment. Shock chlorination (disinfection) is the one-time introduction of a strong solution into the entire water distribution system (well, pump, distribution pipeline, etc.)

When to Shock Disinfect the Well:

Shock chlorination (disinfection) is recommended when lab results indicate a presence of bacteria upon completion of a new well or after pump replacement or repair, when the distribution system is opened for repairs or maintenance, following contamination by flood water, to control iron and sulfur bacteria.

Shock chlorination (disinfection) is recommended in these circumstances to ensure that bacterial contamination is controlled.

Note

:

This system should be used where low to moderate ferrous (dissolved) iron or hydrogen sulfide contamination is known. This filter is most effective where iron and hydrogen sulfide levels are less then 5 ppm. Best removal rates are achieved where pH is between 6.5 and 8.5 and where water contains some dissolved oxygen.

Selecting a water treatment system begins with water test results from a

certified drinking water testing lab

. Such test results should be compared to the water treatment product specifications to ensure that the treatment system being considered is designed to treat:

The substances you want to treat

In the concentrations at which they exist in your water.

There is no one-size-fits-all water treatment technology that addresses all water quality problems. In some cases, one treatment technology may meet all your specific needs. In other cases, you may need a “treatment train”—a series of treatment technologies in a sequence that treat one or more water quality problems. Again, when considering water treatment, use your lab test results as a guide and make sure the technology you are considering is designed to treat the problematic substances in your water.

Most items ships within 1 business day. Used or installed items are not accepted for return.

123 Water Filter