-40%

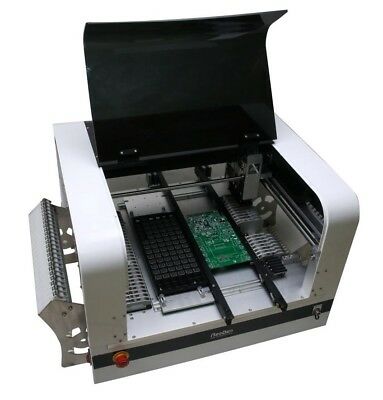

PCB SMT Pick and Place Machine NeoDen4 Vision System 35 Electric Feeders BGA QFN

$ 5220.86

- Description

- Size Guide

Description

NeoDen4 —Automatic Pick and Place Machine

(with Auto Rails and 35*Feeders Version)

Note: tariff, tax, local fees and local support are not included.

Auto Rails and

Feeders

Please kindly note

auto rails

and

feeders

are selectable.

On this listing, the

allocation

is

with auto rails

and

35*feeders(

31*8mm, 2*12mm, 2*16mm).

P.S.

The stand and monitor are included.

Item Description

NeoDen4 is a flexible pick and place machine for all types of production.

With placement rates of

10

,000 cph, up to 48 feeder slots, auto rails and electronic feeders, users can move from prototype into production on the same machine, saving programming and job setup time.

It is a compact placing machine that offers the flexibility (component flexibility, PCB flexibility and production flexibility) and speed to meet the demands of an ever-changing market.

Features

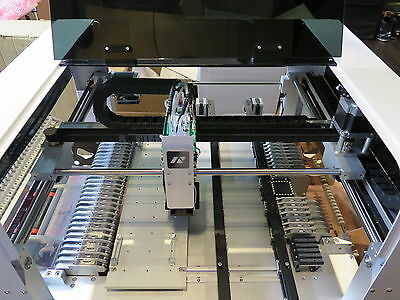

1.

Dual vision system

(up-looking and down-looking cameras),

identify and calibrate the different components at one time,

improves the

accuracy of placement from 0201 to BGA;

2.

Auto rails

, help to achieve continuous placement and solve the problem of long LED bar, ex. 1.5m LED bar;

3.

Automatic electric feeders

, reduce the feeding deviation;

4.

G

eneral conveyor

is supported, so a SMT production line can be setup, which is more time-saving and labor-saving;

5.

Four placement heads

can pick up and calibrate components at one time.

6.

The device supports

remote system upgrade

, NeoDen provides a life long system upgrade service for free to you;

Specification

Model

NeoDen

4

Machine style

Single gantry with 4 heads

Alignment

Stage Vision

Placement Rate

Vision on

5,000CPH

Vision off

10,000CPH(Optimum)

Feeder Capacity

Tape feeder:48(all 8mm)

Vibration feeder:5

Tray feeder:45

Component Range

Smallest Size

0201

Largest Size

32x32mm (Pitch 0.5mm)

Max Height

5mm

Rotation

±180°

Placement Accuracy

±0.02mm

X-Y Repeatability

±0.02mm

Board Dimension(mm)

Maximum

310 x 1,500mm

Minimum

350 x 400mm(Option)

140 x1,500mm(Option)

Main Control

GUI

Electricity Supply

110V/220V

Power

180W

External Dimensions(mm)

Machine size

870(L)x680(W)x480(H)

Packing size

940(L)x740(W)x600(H)

Weight

Net Weight

60kgs

Gross weight

80kgs

Accessories

1

Vibration feeder

1

2

Nozzle

6

3

8G Flash Drive

1

4

Power Cord(3m)

1

5

Rail extension parts

1

6

Double Sided Adhesive Tape

2

7

Allen wrench Set

5

8

Tool Box

1

9

Reel holder stand

1

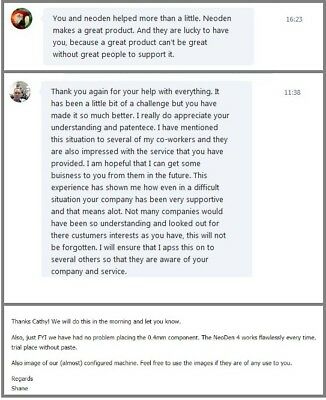

Feedback

Thank you again for your help with everything. It has been a little bit of a challenge but you have made it so much better.

I really do appreciate your understanding and pacience. I have mentioned this situation to several of my co-workers and they are also impressed with the service that you have provided.

I am hopeful that I can get some business to you from them in the future. This experience has shown me how even in a difficult situation your company has been very supportive and that means a lot.

Not many companies would have been so understanding and looked out for there customers interests as you have, this will not be forgotten.

I will ensure that I pass this on to several others so that they are aware of your company and service.

—— Paul

Overall we are quite happy with our machine. We assembly some very complex boards with lots of 0201,0.5 QFN and even some 0.4 BGA components.

——Mario van Asselt

The machine has been great and we are very pleased with it so far.

——Ian

Also, just FYI we have had no problem placing the 0.4mm component. The NeoDen 4 works flawlessly every time.

——Shane Goedvolk

About us

1. NeoDen is a professional designer and manufacturer of desktop pick and place machine with 30 patents and CE certificate.

2. Total 8 Agencies in Japan, India, Netherlands, South Korea, Iran, Turkey, Brazil and Chile, which helps to provide direct service

and better communication in local territories.

3. The after-sale service team consists 14 professional engineers, which helps to respond customers queries and enquiries within 8 hours, provide

professional solutions within 24 hours both workday and holidays.

4. NeoDen use standard export packaging, which is the recycled wooden crate,

not only safer in transportation but also better in environmental protection.

Payment and Delivery

1) Payment

method

: PayPal, West Union, Credit Card, etc

2)

The default delivery method is via TNT (door to door), unless specific requirement from customer.

3) Delivery time: 7 working days.

Warranty

The

guarantee

period is 2 years from the time of purchase and lifelong service support as well as a long-term factory price supply.

NeoDen will

provide online Q/A and troubleshooting support and technical advice service.

Welcome to check more items in our store.

.