-40%

Automatic cicular saw, Programable, straigh and miter

$ 8395.19

- Description

- Size Guide

Description

Universal Automatic Circular Sawing Machine for Straight & Miter Cutting ofFerrous & Non-Ferrous Metals - Saw New in2007, Loader New in 2008

Saw Blade 15.75" Diameter

Working Range

Round 90 or 45 degrees 5.1"

Square 90 degrees 4.7 "

Flat 90 degrees 12" x 0.8" *

Flat 45 degrees 9.6" x 1.1" *

* Reduced in automatic mode

with infeed gripper max.7.4"

Hydraulic system 2.4 HP

Motorized length setting 0.50 HP

Coolant pump 0.13 HP

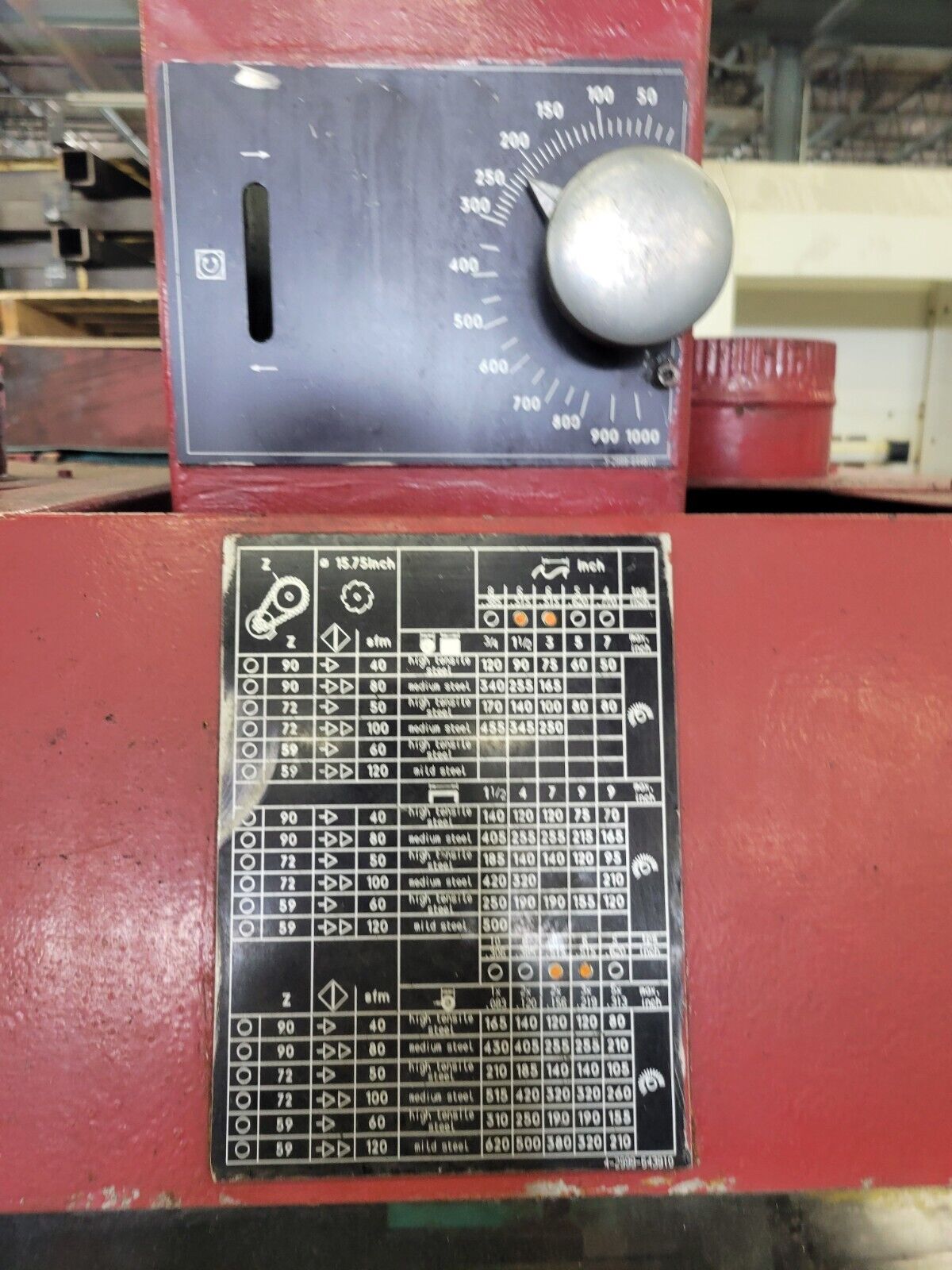

Cutting Speeds With Std Blade 50/100 SFM

Technical Data (Continued)

Saw Blade Feed Infinitely variable to a chart 0- 40 Inches/Min.

Rapid return stroke 130 IPM

Material Feed Gripper Cut length range (standard). .39" to 80"

Weight Machine without accessories, 3,750 lbs.

- Robust back fence with adjustable work-stop,

is via crank handle and allows movement 1.6"

A scale is provided.

- KALTENBACH upstroke blade technology with plasma-nitrified rotating table for straight and miter

cuts. Table rotates from 0o - 180o. Positive stops, which can be overridden, are provided at 45ol90ol-

450.

- Clamping bridge with hydraulic vertical long stroke clamping cylinder 5.3". Clamping on both sides

of the cut. Presetting via crank handle.

supports material on both sides of the cut. Adjustment

maximum to the front and 2.8" maximum to the rear.

- Material feed gripper, left of machine, for cut lengths from .39" - 80.0"(40.0" per stroke). Minimum

height of sharp-edged material0.20". Front gripper is adjustable and has a stroke of 2.8". Rear

gripper has relief stroke to prevent material being damaged on return stroke. Automatic recognition

of material being in the gripper via spring-loaded touch plate and limit switch. Minimum endpiece in

straight cutting is 3.1". Ball bearing mounted transport rollers measure 2.4" x 13". Maximum

material width in automatic mode is 7.5" (reduced when using quick-change clamping jaws). Feed

gripper unit can be swung up out of the way (electrically interlocked) to allow semi-automatic

operation. The safety protection hood has to be closed during cutting process.

- NC preselection for programming up to 20 programs, with up to 20 saw orders each. Bar or quantity

oriented processing. Automatic motorized length setting. Subtracting piece counter with automatic

switch-off function. For urgent jobs, data can be entered directly without having to store it.

- Hydraulic saw blade feed, infinitely variable to a chart.

- Electronic blade height setting via push button. Toothed segment with encoder. Automatic reset at

machine start.

- Raisable safety hood for machine and feed gripper unit, with electrical interlock.

- Working area illumination.

- Large electrically interlocked machine door facilitates saw blade and chip sprocket changing.

- PLC control with control cabinet. Ergonomic arrangement of control elements. Lockable switch is

provided for set-up mode.

- Hydraulic power pack (delivery 6.5 GPM).

W167 N5905 Greenway Circle . Menomonee Falls, Wl 53051

Phone: (262) 703-0400 . Fax: (262) 7B-4477

Item ll04 - Standard Equipment (Continued)

- Coolant system with pump. Coolant is supplied to both sides of the blade immediately prior to

entering the cut. Coolant flow can be adjusted externally from the operator position.

- Saw blade 400 mm diameter. Chip drawer runs on ball bearings. Pin chip wheel and roller type chip

remover for the saw blade. First filling of hydraulic oil, gearbox oil, coolant, tools, and manual.

Sales Price ,900

Item ll04 -KKS 400 NA, including all standard equipment

Included Equipment

Item 1111 - Hydraulic horizontal clamp, presetting to material width, stroke 0.3"

Item 1180 - Hydraulically retractable trim-cut device. Lever for automatic

endpiece regulation. Trim-cut length adjustable. Required for

automatic loading magazines

Item9999 - Coolant atomizer system in addition to flood coolant system

(compressed air necessary).

Item6962 - Automatic Inclined Magazine LM for round and square material

Sliding brackets attached to the magazine and lifting arms (no

adjustment of the angle of inclination required).

The inclined magazine comprises the input roller conveyor and basic equipment which is designed

for initial stock lengths 6' - 20' (16'for light sections). The individual components are pre-mounted and

connected by couplings and plug connections to the system. Basic version mounted on front side

of input roller conveyor.

Working Range: Round Material ......in 0.6' - 5.1"

Rectangular Material (width)..................... in 0.8' - 5.9"

Maximum Weight, per material bar, 20'.. lbs 1,650 lbs.

Maximum Weight, load for magazine..... lbs 8,800 lbs.

Storage Width ........43.3"

Input roller conveyor with ball-bearing supported transport rollers 2.4" x 13.0".

Drive via chain and sprocket at speeds of 24148 FPM.

Vertical guide rollers position the material on the input roller conveyor.

Central pre-adjustment of the material width with crank handle according to scale.

Electro-mechanical device for the separation of the bars coming from the magazine onto

the roller conveyor (drive 0.5 HP).

Item 6964 - Stillage for material bundles, width 28", mounted at the rear of the

magazine for stock lengths 20'...